Advanced Manufacturing Program Overview

The Advanced Manufacturing Degree at Lakes Region Community College consists of 11 major core courses 5 of which are the core courses of our Advanced Manufacturing Certificate program. Successful students should have the necessary skills to enter the manufacturing workforce, or excel in current manufacturing employment, into positions a step higher than entry level. Students will have an understanding of manufacturing operations and processes.

In addition, students will have acquired skills for decision making in the manufacturing environment using quantitative and qualitative data. Students will have knowledge in

- Materials

- Processes

- Quality control

- Machine Operations

- Machine set-up and tool section

- Employee empowerment skills

- Critical thinking skills

- Oral and technical communication skills

- Operation management skills

Program Outcomes

Students successfully completing the Advanced Manufacturing Degree Program will have the following skills:- Mathematic skills necessary to solve manufacturing problems through the understanding of fractions and decimals, algebra, geometry, trigonometry, linear equations, roots, geometric figures, usage of tolerances, interpretation and usage of formulas and proportions, and practical applications of geometry and trigonometry.

- The ability to read and interpret blueprints and engineering drawings.

- Understanding of machine tools and machine tool operations such as milling, turning, drilling, cutting, grinding, and chamfering.

- Advanced CNC machine operations skills including offsets, work offsets, G-code programming, machine zeroing, and circular interpolation, set-up, tool selection, material selection, and operator maintenance.

- Computer Aided Manufacturing (CAM) and CAM-Mill skills in processes such as contouring, cycle time estimating, tool selection, material specification, cutter compensation, parameter changes, contour applications, roughing, finishing, and tool paths.

- Operational Management skills in strategic decision making using tools such as forecasting, basic inventory models, aggregate planning, master scheduling, materials requirements, and scheduling of operations.

- Understanding of procurement, inventory movement, storage of materials, and production flows.

- Lean manufacturing principles such as line balancing, standard work, waste elimination, 5-S programs, employee empowerment, quality, lean production flow and inventory control, as well as facilitation techniques.

Total Credits: 3 Total Credits: 3 Total Credits: 3Course Sequencing

First Year

Social Science Elective

Humanities/Fine Arts/Foreign Language Elective

Second Year

Liberal Arts Elective

Course Sequencing

Certificate Requirements

Joseph Smith

Electrical and Advanced ManufacturingInstructor, Advanced Manufacturing; Department Chair Advanced Manufacturing and Electrical Technologies

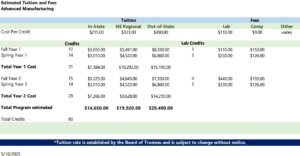

Associate Degree