MACHINING

> PROGRAMS > CAREER & TECHNICAL EDUCATION > INDUSTRIAL & ENGINEERING TECHNOLOGY PROGRAMS > MACHINING

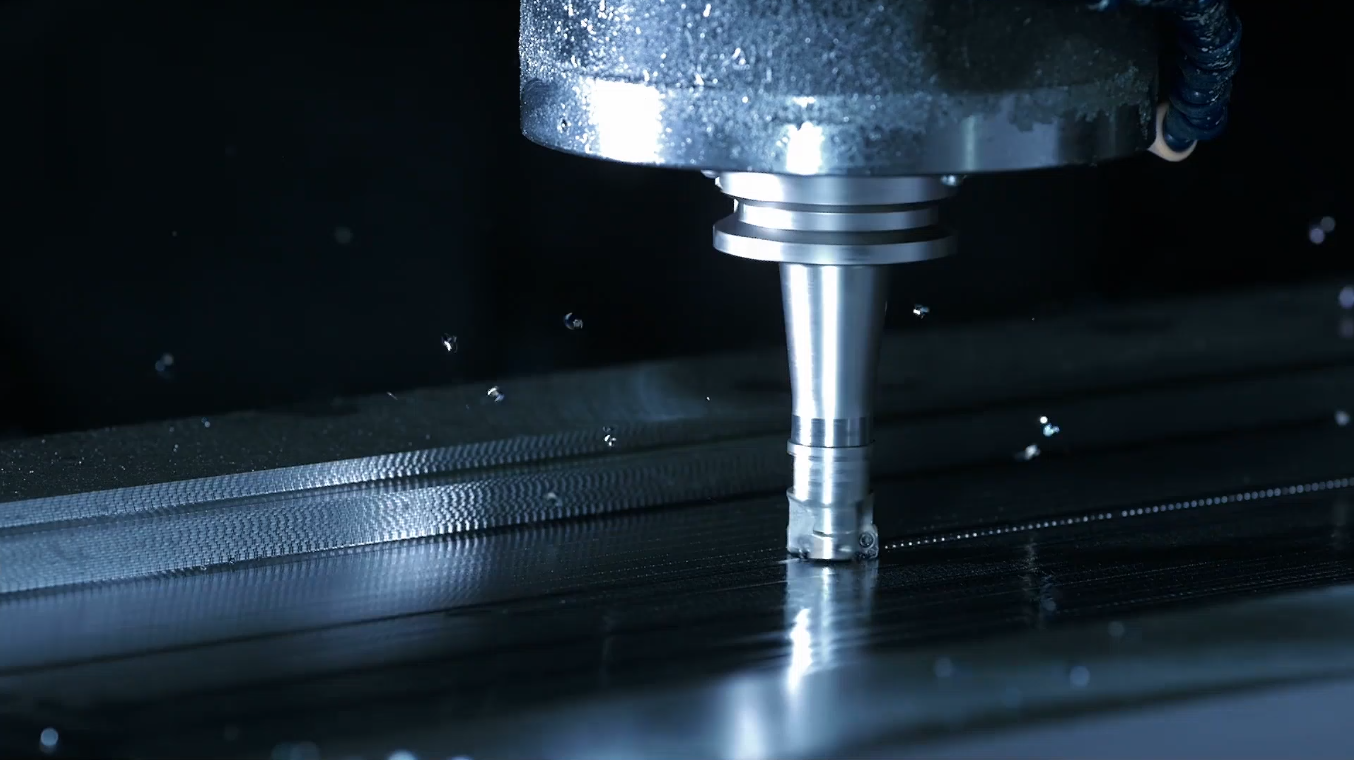

NCTC’s Machining Technology program prepares students for careers in manufacturing, oil and gas, and even aerospace. Machinists work in manufacturing, construction, or specialized shops using machine tools to make or modify parts, primarily made of metal. While machinists in our program will learn various foundational welding techniques, their studies will also include operation of computer numeric control (CNC) equipment, more traditional tool and die mechanical machinery, mathematical applications, and more.

Career Outlook:

Machinist: Responsible for installing and operating a wide range of tools to create precision parts and instruments from metal. They may fabricate and modify pieces and parts to upkeep the maintenance of industrial equipment, and are also knowledgeable in mechanics, mathematics, metal properties and mechanical procedures.

Tool & Die Maker: Work on verifying dimensions, alignments, and clearances on finished products to ensure maximum performance and that all standards are adequately met. They lay out metal, set up and operate machine tools, fit and assemble parts and make any necessary adjustments to dies, cutting tools, gauges, and so forth to guarantee optimal performance.

Machining Program details

In a mixture of online, hybrid, and in-person courses at our Gainesville campus, our students walk away with undeniable skills making them competitive when entering the workforce. Our machining program will teach you layout, blueprints, jig bore and grinder, precision measuring, CNC, G codes, tool paths, and precision production in our state-of-the-art lab. You will also be able to demonstrate improved communication skills, proper workplace etiquette such as safety practices, know all about basic machining procedures, and have access to hands-on practice that will be applicable to real world situations.

Through the completion of our program, you will earn an Occupational Skills Award (OSA) and a Level 1 Machining Certificate, on your way to an AAS Machining Degree at NCTC. Upon completion of the Associate of Applied Science Degree, students will be able to:

Demonstrate mechanical reasoning, form perception, and spatial relations.

Demonstrate the attributes of a positive work ethic.

Demonstrate the perception and spatial relations in the applications of geometric construction.

Basic Level 1 Certificate

The Basic Level I Workforce Certificate can be completed in one semester through a mix of in-person, hybrid, and online classes. The certificate program teaches the basic welding skills and technical knowledge for an entry-level position in the welding industry. Upon successful completion of the Basic Welding Certificate, you will be able to:

Demonstrate improved communication skills.

Demonstrate proper workplace safety practices.

Demonstrate the use of basic machining procedures.

Demonstrate an understanding of Computer Numerically Controlled (CNC) machining.

Demonstrate a basic understanding of blueprint reading for the machining trade.

Courses and credit hours (#) required to earn the Machining Basic Level I Certificate.

First Semester

MCHN 1338 BASIC MACHINE SHOP I — (3)

MCHN 2303 FUNDAMENTALS OF COMPUTER NUMERICAL CONTROLLED (CNC) MACHINE CONTROLS — (3)

MCHN 1343 MACHINE SHOP MATHEMATICS — (3)

MCHN 1302 PRINT READING FOR MACHINING TRADES — (3)

MCHN 1341 BASIC MACHINE SHOP II — (3)

Total credit hours for this semester — (15)

Total Credit Hours — (15)

Capstone Requirement: Students completing the certificate must pass a comprehensive exam and lab with a score of 70% or higher. The exam and lab are embedded in the curriculum for MCHN 1341.

Level 1 Certificate

This certificate can be completed through a mix of in-person, hybrid, and online classes. The program is designed to take one year to complete. Upon completion of the Level 1 Workforce Certificate, you will be able to:

Demonstrate improved communication skills.

Demonstrate proper workplace safety practices.

Demonstrate the use of basic machining procedures.

Demonstrate the ability to use precision measuring tools.

Demonstrate the relationship between Computer Aided Manufacturing (CAM) and Machine Code.

Demonstrate proficiency with CNC mills and lathes.

Demonstrate pattern development for the machining trade.

Courses and credit hours (#) required to earn the Machining Level 1 Certificate.

First Semester

MCHN 1338 BASIC MACHINE SHOP I — (3)

MCHN 2303 FUNDAMENTALS OF COMPUTER NUMERICAL CONTROLLED (CNC) MACHINE CONTROLS — (3)

MCHN 1343 MACHINE SHOP MATHEMATICS — (3)

MCHN 1302 PRINT READING FOR MACHINING TRADES — (3)

MCHN 1341 BASIC MACHINE SHOP II — (3)

Total credit hours for this semester — (15)

Third Semester (Summer)

MCHN 2435 ADVANCED CNC MACHINING — (4)

MCHN 1326 INTRODUCTION TO COMPUTER-AIDED MANUFACTURING — (3)

Total credit hours for this semester — (7)

Total Credit Hours —(36)

Capstone Requirement: Students completing the certificate must pass a comprehensive exam and lab with a score of 70% or higher. The exam and lab are embedded in MCHN 2435 and MCHN 1326.

Machining AAS

This degree can be completed through a mix of in-person, hybrid, and online classes. The program is designed to take two years to complete. Upon completion of the Associate of Applied Science Degree, students will be able to:

Demonstrate mechanical reasoning, form perception, and spatial relations.

Demonstrate the attributes of a positive work ethic.

Demonstrate eye and hand coordination.

Demonstrate the application of and the ability to use the common hand tools.

Demonstrate the ability to use the proper tool necessary for the related task to be performed.

Demonstrate the perception and spatial relations in the applications of geometric construction.

Courses and credit hours (#) required to earn the Machining AAS.

First Semester

MCHN 1338 BASIC MACHINE SHOP I — (3)

MCHN 2303 FUNDAMENTALS OF COMPUTER NUMERICAL CONTROLLED (CNC) MACHINE CONTROLS — (3)

MCHN 1343 MACHINE SHOP MATHEMATICS — (3)

MCHN 1302 PRINT READING FOR MACHINING TRADES — (3)

MCHN 1341 BASIC MACHINE SHOP II — (3)

Total credit hours for this semester — (15)

Fifth Semester

SPCH 1311 INTRODUCTION TO SPEECH COMMUNICATION— (3)

BMGT 1327 PRINCIPLES OF MANAGEMENT— (3)

ARTS 1301 ART APPRECIATION— (3)

MCHN 2380 COOPERATIVE EDUCATION-MACHINE TOOL TECHNOLOGY/MACHINIST— (3)

Total credit hours for this semester — (12)

Total Credit Hours — (60)

Capstone Requirement: MCHN 2380 Cooperative Education is the capstone experience and may not be substituted. The Capstone requires the student to accumulate work experience related to the program. In addition, a comprehensive exam and lab must be completed with a grade of 70% or greater. The Capstone course should be taken the last semester before graduation.

Build your Future

Don’t wait any longer! Contact our team of Advisors to begin your enrollment. You can get started as soon as next semester and be on your way to your dream job.